PYPLOK® IN OFFSHORE

With demand for energy growing day by day, the need to explore and exploit energy hidden in deep seas are increasing. With increased exploitation comes scarcity. Hence the need to discover and exploit energy in difficult environments.

With difficult environments comes the problem of environmental effects like corrosion.

The challenges faced by customers in offshore environment are as follows:

With difficult environments comes the problem of environmental effects like corrosion.

The challenges faced by customers in offshore environment are as follows:

- Less time for repair or shutdown

- Avoid hot work

- Corrosion

- Skilled Labour

- Reliability

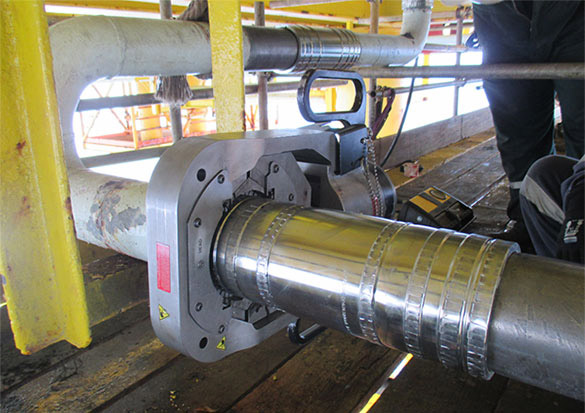

Cu-Ni Pyplok® in Offshore

4" NPS Pyplok® installed on a Drilling Platform